In a Black Friday sale in 2024, I got a new Bambu X1C. This page journals my thoughts about printing with it.

Some of the items are about minor/trivial/cosmetic issues, maybe just passing thoughts of trivial improvements, so don't put too much weight to them. They are just observations.

Overall, my first impressions are that the printer is fantastic. However, on this page, I will mostly only comment about negative things, and problems, since these are important to me to note. So this might incorrectly give a negative bias about the printer. This is not a printer review page, but a problem/thought journal. In particular, if/when I find an answer, I won't go and edit the text where I originally pondered over that question.

My previous printer was a decade old Ultimaker 2. Compared to that, Bambu X1C is from another planet, absolutely marvelous.

The instructions that guide through the unboxing are really nice. They walk the user through every action of setting up the printer. The one thing that the instructions did not mention are the two foam inserts at the bottom of the printer under the print bed. I suppose those are not there for permanent cushioning, so I got rid of them as well.

When I was inserting filaments for the first time, I first inserted white PLA in the first AMS slot. The automatic feeder mechanism pulled the filament in, and autodetected white PLA. OK so far.

Then I inserted green filament in the second AMS slot. However, this time the feeder motor got stuck in an infinite loop attempting to pull the filament in, but somehow not making a "bite" on the filament, and the filament was not moving in. Even after attempting to hand-assist the filament in by many centimeters, the feeder would not work, but was stuck spinning the motor.

I pulled out the green filament and attempted to feed it back in to the second AMS slot. The same thing happened, the feeder motor got stuck in an infinite loop, without pulling the green filament in.

Then I took out the green filament, and put it in the third AMS slot. This worked perfectly, and I got green PLA detected automatically.

Then I tried to add another roll of black PLA in the troublesome second AMS slot. Surprisingly, this also worked perfectly. Not sure what to make of it.. maybe I fed the green filament somehow poorly the first two times in a row, or does the second AMS slot not support green color? :p

Then I inserted support material for PLA in the fourth slot.

Some time after, I noticed that neither the black PLA in the second slot nor the support material PLA in the fourth slot were autodetected, but were showing up as "?" in Bambu Studio. The 1st and 3rd slot filaments were autodetected. (All were Bambu filament with RFIDs) Somehow the RFID detection is not 100% foolproof.

I manually assigned the PLA information in Bambu Studio to pass the issue.

Tried out a test print with the Benchy model. It came out perfect, although there is an observable line artifact in the result. Googling, it looks like this is a result of varying print speed on different Z levels. Interesting. Not a big deal here, though for my own aesthetic prints I will need to look out that I don't get visible layer lines in the print result.

Bambu has made some poor technical decision in the Windows 10 Bambu Studio program, that they rely on some obsoleted Microsoft Windows Media add-on extension to be able to observe live printing. I was unable to install that extension, even after visiting Bambu's tech support page. I really like how Bambu Labs approaches offering troubleshooting tips, they think through the customer experience - however, they should definitely drop this dependency to the Windows Media add-on, and use another more deeply bundled video streaming software component to implement live printer video streaming.

I don't have a solution to this, and the steps offered in the Bambu troubleshooting page do not work. For now, I am observing my prints from Bambu Handy app in iPhone only.

Bambu advertises Lidar calibration to improve print quality. Reading the webs, some people are commenting that the Lidar is a gimmick and there "just for show."

Likewise, there is a carbon filter, but people are talking about the built-in filter being wholly inadequate, and adding custom mod Bento filter boxes with HEPA filters to improve VOC filtering.

I don't know at this point who to believe more. However, observing these types of user sentiment makes me a bit cautious. I would wish to read the user sentiment about Lidar being "it really helps", and to not see YouTube videos about "the carbon filter is useless." I guess I will get to see which way to lean on these after some weeks/months of use.

This printer does cause less of a PLA smell for sure than my Ultimaker 2 used to.

I like to check on prints on my iPhone, so I have Bambu Handy installed there. I also have an iPad, and occassionally I would like to use that to check up on prints. To my surprise, Bambu doesn't allow logging in from the iPad, if I don't log out from iPhone first. This restriction feels unnecessary and arbitrary. It should be possible to stay logged in from multiple mobile devices simultaneously.

If there really is some hard technical reason, then it might be better to log out the previous device when the new device attempts to log in, as opposed to preventing the new device from being able to log in at all. But ideally, two devices should just be able to be logged in at the same time - can't think why not.

I wanted to change a roll of filament in the AMS, but how do I do that? Can I just press on the thumb latches in the AMS, and pull the filament out by hand? Or does that cause undesirable strain on the filament feeder motor, and there would be a Unload filament feature in the UI that would be the "proper" way to do it instead?

Pondering this problem for a moment, I did find the Unload filament option, but that seems to be for unloading the currently active filament from the print nozzle, not for unfeeding filament up from the feeder altogether.

Not sure what the right answer is, so I ended just pulling the filaments out by hand. Maybe that is how it is done.

Ouch, I notice that switching filament is painful to the thumb really quickly. The thumb latch one presses on to unlock the filament in AMS is really awkward. I hope that gets redesigned in the future, this is painful, and there is no clear stop to observe when one has fully depressed the thumb latch. I.e. the feel on the thumb latch is springy and there is certain amount of flexing "give" at the end. This is not that great of a design.

One of the great features that Bambu advertises is the capability to seamlessly switch from one roll of filament to another identical one, when the first roll runs out.

In this Reddit thread, it has been observed that there can be a patch of tape that can get stuck in the AMS feeder when a roll of filament is about to run out. Wow, that could cause catastrophic jams for sure. That is pretty horrible design, hopefully Bambu removes that tape at the end of their filament rolls in the future.

I got the Halloween PLA combo: black, white, red and glow orange PLA. Inserted all those spools in the AMS.

I found a nice print of Christmas gnomes in Makerworld, which I notice uses the exact same colors: black, white, red and orange.

However, when I open the project in Bambu Studio, the colors are wrong, because I inserted my filaments in a different permutation in my AMS, compared to the original author of the model I am about to print.

I notice I can fix this by double-clicking on the filaments to reassign them, so not a big deal. However it seems like this would be something that Bambu Studio software could automatically have done - after all it should have all the needed information to semantically map the original author's filaments and current AMS setup filament permutations together. I wonder why this doesn't happen automatically, or maybe I am missing some feature to make that happen.

Not a big deal of course, though the first time when I was fixing this, I realized only after the print that I had fixed the mappings incorrectly, which resulted in unintended print colors.

I have 128GB SD cards, which Windows only allows being formatted to exFAT. The FAT32 filesystem is not possible with 128GB cards. However it looks like Bambu needs FAT32, and doesn't support exFAT? At least it considered my 128GB exFAT card to be unformatted.

In some of the prints, I would like to create slower timelapses, or to record the full print video on an SD card to be able to observe specific details about the print process afterwards.

However, it looks like even though the thing has a webcam and a SD card slot, it is not possible to control the timelapse recording speed?

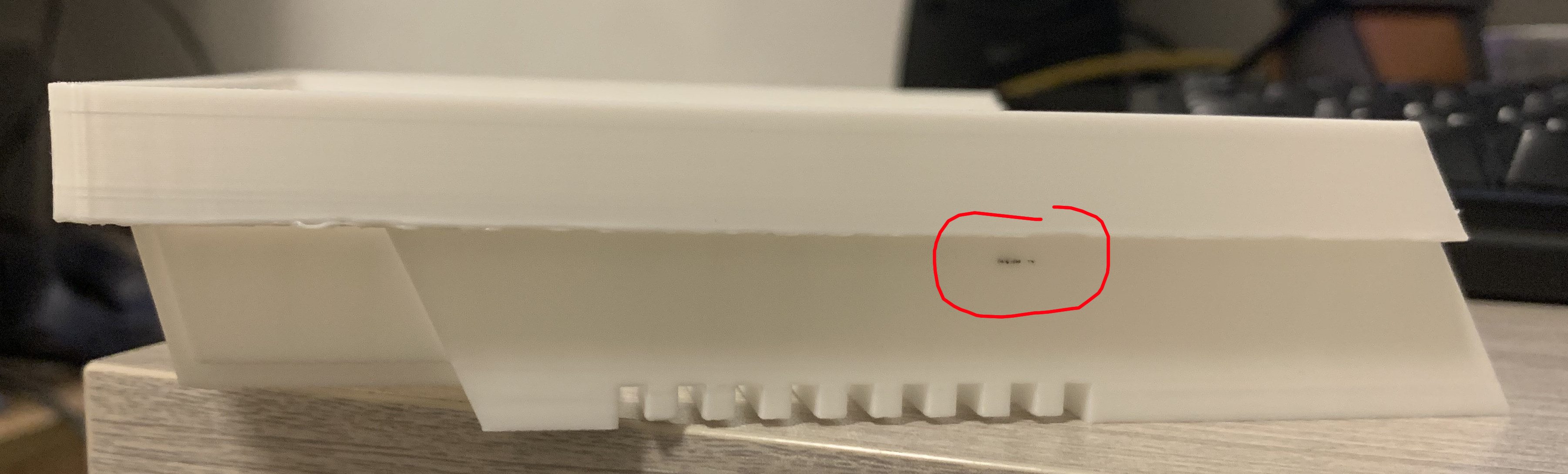

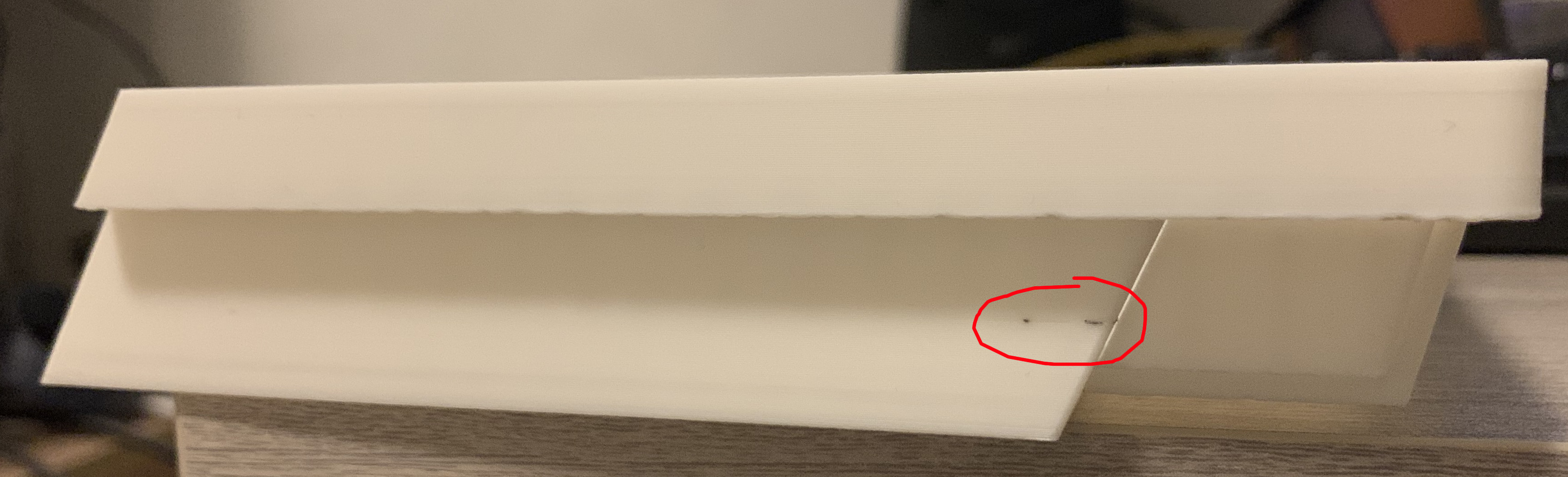

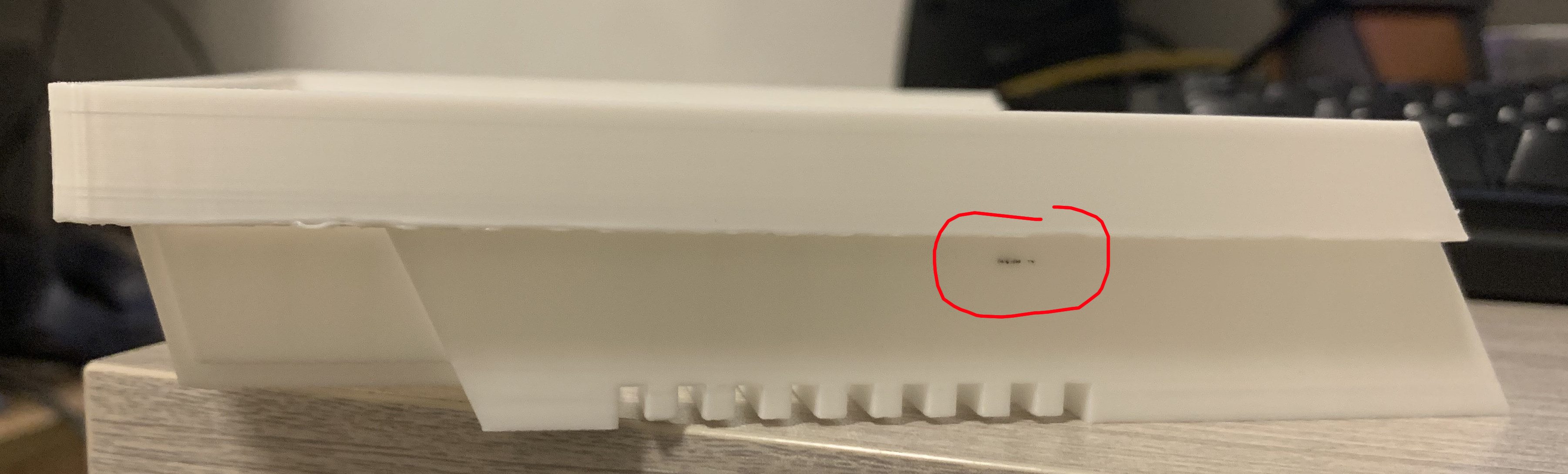

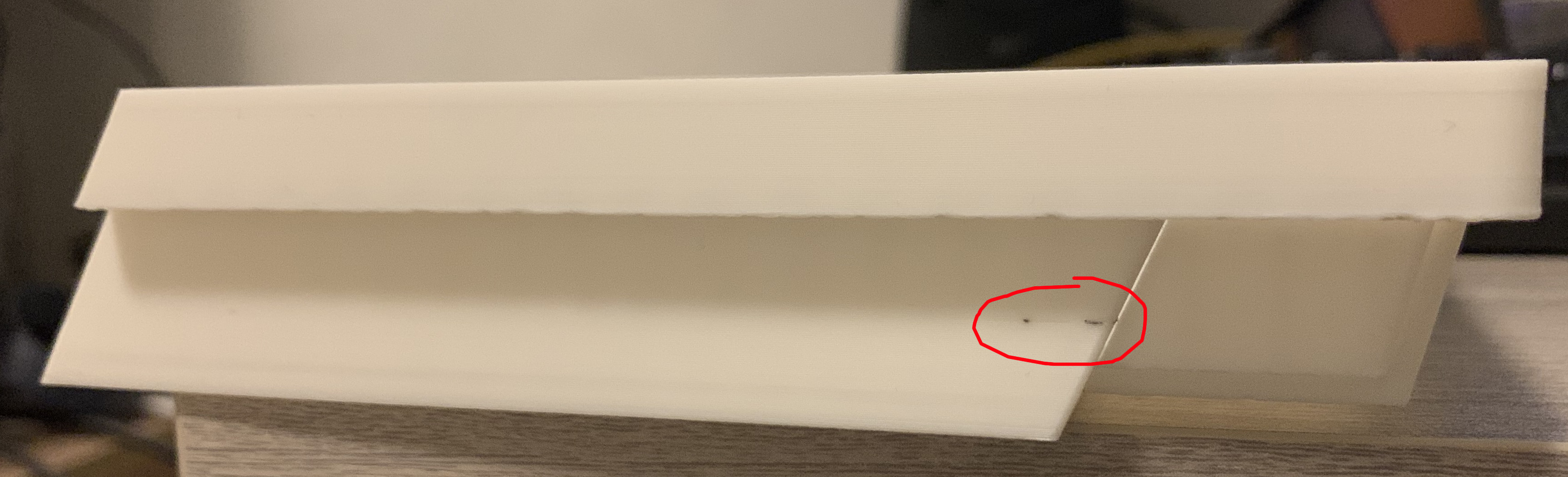

I am designing a case for my project, and now after a test print I notice that the Textured PEI plate has the Bambu Labs logo on it, which gets imprinted on anything that is print with this plate. This is pretty frustrating. I think I probably need to get another print plate just to get rid of being an ad for Bambu Labs. Not nice Bambu :( Where do I send my Bambu Labs ad invoices?

(or does the Bambu logo imprint somehow "wear off" from the plate after a couple of prints? This was my first print with this plate after all. In any case, this does not build brand trust for me)

Had a really odd moment when starting a print: on my desktop PC, in Bambu Studio, I started a print, and got the "uploading to cloud" % progress bar. It ran into 100%, and I expected the printer to soon after start printing.

Then some 10 minutes after I realized: "wait, the printer hasn't started running at all." I go and look at the printer, and it is just sitting there idle, touchscreen blank, and no activity.

I go back to Bambu Studio, and it is also not showing the print as running. I'm thinking "Surely I did start the print, I remember the uploading to cloud 100% progress bar run, and all that." What happened?

Well, I restarted the print, and this time the printer did actually start running. Am I getting old? Did I actually not start the print the first time? Or did the printer somehow ignore the print command? I'm starting to doubt myself.

I am seeing how the textured PEI plate is much superior to the glass plate that my Ultimaker 2 had.

Now I see my plate has some grease marks on it, so I wanted to wash it. The guide is saying to use dish soap to wash it. I am wondering which Finnish brand dish soap would be the closest.

Used Fairy, that seemed to do the trick.

So far the printer is just perfect: everything has worked on the first try, even printing a prototype of my own project case design, which I just threw on to the printer with little examination of the slicing paths (which would have needed careful attention with Ultimaker 2).

However, something that I observe from watching the live webcam while the thing is printing: the print plate occassionally wobbles/shakes up and down a little bit as the print nozzle moves during the print. I wonder if that is normal...?

So far all the prints have been just absolutely perfect, so I presume that it is, though the effect does seem pretty hardcore to see, as the print plate does shake up and down. Or maybe the effect is just pronounced since the webcam is located so close in perspective to the print bed.

I got a refill spool of filament. The very last step in the spooling instruction of the filament asks to place a sticker from the refill box to the side of the spool. (so you won't forget what filament it is). But there were no refill stickers that came in the box. Weird. Well, I guess I do still have my eyeballs to look at the color of the filament to see what it is. Maybe the instructions text was just outdated.

I also got a roll of that magical looking water soluble PVA support filament. When attempting to print with PVA, Bambu Studio gives a warning text to dry out PVA before use.

However, this makes me confused: since the PVA filament comes vacuum sealed, doesn't that mean that the filament should be suitably dry already out of the box? Reddit threads like this suggest that the vacuum sealing does not mean that the filament would be dry. (What is the vacuum sealing then for?)

Ok, so better dry it then. I'm looking at the Bambu X1C "Dry Filament" utility feature. It asks to select the filament to dry. But there is no "PVA" option to select in the menu! There's tons of other filament materials to choose, but PVA is not mentioned.

Does that mean that Bambu X1C cannot be used to dry PVA filament? The above linked thread does mention "Dry out the same as PLA." so I'll try that. The same comment also mentions "12 hours at 55c." Check.

Actually, scrap that. Searching Bambu's website finds their own filament drying help page. In that table, I see that PVA is listed to have identical parameters with PA. So while the drying utility UI does not list PVA, it does list PA. So I think I'll use that.

It would be good for Bambu to add PVA also in that UI list. Not having it seems like an oversight.

I thought to double check before doing the PVA heating with the PA option, to check to update the firmware. I have already updated the firmware as the first thing when I got the printer on 30th of November. But, to my surprise, the Firmware menu now again lists there being an updated firmware available. And oddly, this page suggests the last firmware update was in August.

This suggests that Bambu does not update immediately to the latest firmware when one does a firmware update while the printer is several firmware versions behind? Instead, it seems to update one version at a time(?), so to get the latest firmware, one has to do several updates in a row? Well, updating now (again). I forgot to record what the version before was, but after the update, I am now on 1.08.02.00, which is listed as the latest version on the above webpage as well.

Looks like updating the firmware did not add PVA as an option in the filament drying menu. So I'll try drying it with the PA option.

In YouTube videos, I've seen two "impossible" PVA prints circulated: one is a hollow rook with a DNA helix inside it, and another is a 20-sided die inside a dodecahedron. Tried to print both, but both failed due to the PVA filament not flowing properly. I had dried PVA inside the printer for 8 hours before attempting the print.

I'll try drying the filament overnight for full 12h next.

Today I'm reprinting the D20 die with PVA supports. This is a 22h print. Fingers crossed.

Now I notice that after the previous firmware update, the printer fans have become considerably louder than before the firmware update. Looks like this has been commented on before, where it is mentioned that the fan duty cycle has been increased to improve printing reliability? Oh well.

Yay, the long print with soluble filament worked, and the PVA did not behave as badly this time. There are some random specks of PVA lying around inside the print chamber, which I find doesn't generally happen with PLA. So the flow of PVA is not quite as perfect as with PLA. Nevertheless, it looks like the print did stay in place, and I put it to soak in water.

Actually, after all the PVA has dissolved, I realize that there is one edge of the icosahedron that was printed incorrectly, and did not hold in place. I don't know why that is, but it didn't just quite work out.

I notice that it is the Chamber fan, which is running at 80% speed that causes most of the noise after the firmware update. I did recalibrate the printer after firmware update, but that did not help with the Chamber fan noise. I don't think the Chamber fan was running this loud before the update.

I'd love to know if it was possible to give the printer a Noctua fan mod.

Today I stumbled onto this help page, which says:

"When printing a filament whose glass transition temperature is lower than 60 ° C (such as PLA, PVA, or TPU) and the head bed temperature is set higher than 45 ° C, it is recommended to open the front door and remove the top glass cover to avoid material softening caused by thermal creep and abnormal extrusion or clog of the filament."

This is really peculiar place to read about this, for two reasons that come to mind:

Hopefully Bambu improves on these two points: maybe a future iteration of the printer would have a better top lid design that can be operated while stacking the AMS on top.

In the meanwhile, now I understand those manual mods that some people have been printing.

I started a print, but was absent minded and had forgotten to put the print plate back in the printer.

The printer very helpfully gave an error that the print plate marker was not detected. I replaced the print plate back in the printer, and clicked on "Resume Printing (problem solved)" button.

The printer started doing something as if to resume the print, but after a few minutes or so, it somehow stalled. I waited for some ten minutes, but nothing happened. Bambu Studio is saying the printer is in "Auto bed leveling" stage, but nothing is actually progressing.

I stopped the print and started it from scratch again proper. Looks like there is some kind of resume bug that the printer doesn't properly resume from the above error. Not critical though, since one can start the print from scratch at least.

Today I got something odd. I have AMS with black and white PLA loaded in it. I had printed a model with black PLA. Then, I printed my next model with white PLA. In that printed model, more than an hour into the print, there are these odd specks of what seems to be black PLA (or burned up plastic?) in the new model. These specs appear some hundred Z layers into the new print, and not e.g. at the start of the print. I wonder if that means there can be small strings of previous filament that can get stuck "long term" in the tube/nozzle from a previously used filament somehow? Yikes...

(This was all printed with Bambu Studio filament, with default filament settings and filament purge settings)